In a previous article, we mentioned the three main features that determine the choice of your blanket :

- the length

- the power

- the action

The best blank is the one that meets your needs

In this respect, it's vital to define precise specifications in order to make the right choice of blanks, and not to hesitate to do your research. The best of all blanks is not a specific reference, but simply the one that perfectly matches your needs!

A sheet of carbon

In simple terms, a blank is a sheet of carbon impregnated with resin and wound around a mandrel to form a conical tube. Today, the vast majority of blanks are made from carbon, but there are still some fiberglass models for specific uses.

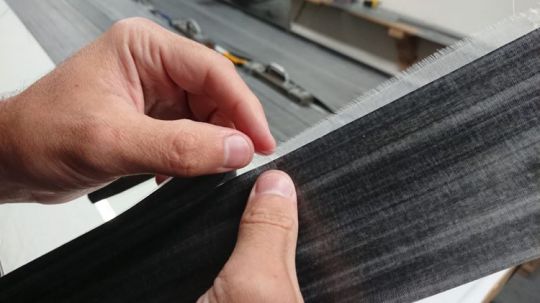

At the design stage, when carbon comes out of a manufacturing plant, it takes the form of bundles of wire which are braided together to form a web. This is then impregnated with a thermosetting resin to bind it all together.

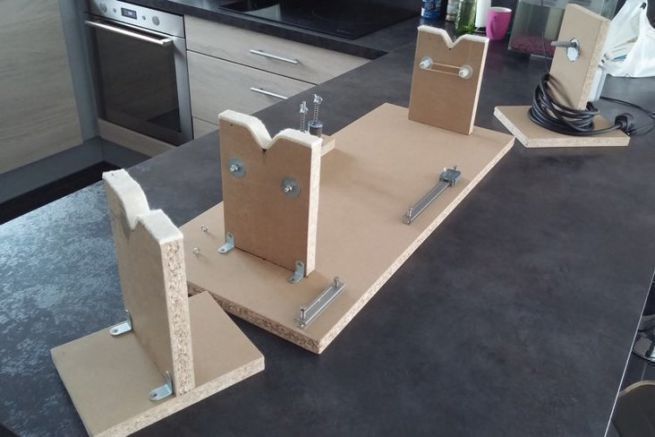

From this point on, the carbon sheet is cut, then wound around a mandrel using a press, and finally baked to produce the desired conical cylinder.

Scrim

Finally, this carbon cylinder is resin-bonded to a "scrim" whose function is to allow the blank to regain its round shape after being compressed. In fact, when your blank is put under tension, it no longer becomes round but oval, which is where the scrim comes in.

Depending on the quality of the blanks, the scrim is made of fiberglass or carbon for the top of the range. North Fork Composite's Xray blanks are even available as "scrimless" blanks.

Material quality

Carbon fibers are classified according to the quality of their modulus. This is expressed in Million PSI. We thus obtain HM blanks (high modulus) with a value of over 50 million PSI, IM blanks (intermediate modulus) with values of around 35 million PSI, and below these values SM blanks (standard modulus).

The quality of the material used determines the blank's tolerance to bending, resonance, lightness, strength... This quality is chosen according to your needs. When you're fishing in a very crowded environment and don't need very high resonance, an SM blank, because of its robustness, is much better suited than an HM, for example.

And resin quality

Blank quality also depends on the resin used to bond the carbon sheet and the composition of the scrim, both of which influence the intrinsic virtues of the tool produced. Blank manufacturers are currently focusing their research on these two components.

Now that you know how the core of your rod is made and to what extent the characteristics of the materials used can influence your choice according to your needs (need for resonance, strength, lightness...), we'll look in a second part at how the blank's geometry enables you to determine its action, casting power and power reserve.

/

/