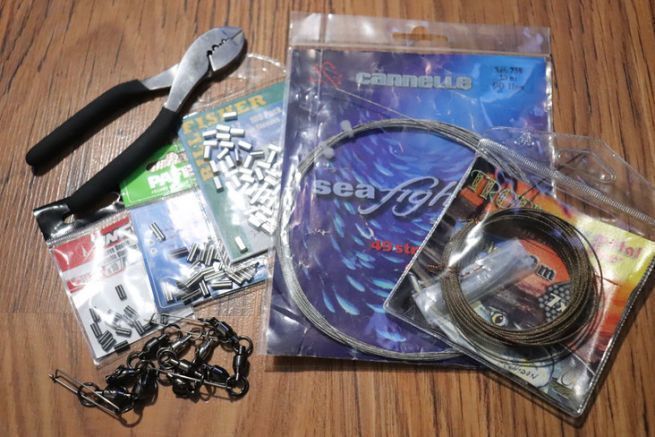

Making a steel leader

The principle for making steel leaders is the same whether it's a single or double sleeve, the difference being that you have to make sure you use the right pliers for the sleeve you're using.

Pass the line through the sleeve once, if necessary, slide in the desired accessory such as a swivel, and pass the line through the sleeve again to form a loop at what will be the end of the leader. If there's enough room in the sleeve, pass the line through it a third time, taking care not to overlap.

If the cable frays during the operation, simply cut off the faulty part and you'll have a nice, easy-to-handle cable again. Once crimped, it won't move again.

The clamping stage

Using the crimping tool, tighten one side, then the other, rotating the assembly through 180 degrees. Tighten moderately, to avoid damaging the sleeve.

The sleeve is made of a soft alloy, and crimping it too tightly will cause it to crack. If in doubt, it's best to cut off the crimped section of wire and start again. Finally, cut off the excess wire with wire cutters.

It's that simple! To make a loop on the other side of the assembly, simply follow the same procedure. This doesn't require any special equipment and, above all, allows you to make your leaders just the way you want them. Particularly for strong exotic fishing, for which there are few ready-to-use leaders!

What about titanium?

To make titanium leaders, the procedure and accessories used are the same. However, instead of passing through the sleeve three times, twice is sufficient, as the rigidity of titanium prevents it from being passed through three times.

/

/