Goal

The purpose of the operation is to remove dirt and old grease from the reel, replacing it with new grease. This keeps the reel running smoothly, and removes external elements, such as sand and braid dust, that could degrade it.

Council

When disassembling the reel, you must place each disassembled element in the order in which it was done. Thus, when reassembling, it is enough to repeat the same action, in the opposite direction. It is also possible to take pictures to see the position of each part, at each stage of disassembly.

How it works

- Remove the cover on the side, where the magnetic/centrifugal brake and the coil are located.

On this model, a screw holds the cover. - If the inside of the bearing is dirty, clean it. For reels with a magnetic brake (as shown in the photo), check the bearing for damage. The bearing should turn without hard spots or noise.

Coil and magnetic brake. - Remove the small retaining screw on the crank, then remove the plate that serves as a lock nut. With the 10 mm wrench, remove the nut holding the crank, turning clockwise.

Disassembly of the crank. - Remove each item carefully and place them in the same order. Many of them, including the washers, have a very specific meaning. If you look closely, the two brake compression washers are curved washers (Belleville type), which is why it is important to respect their direction of assembly.

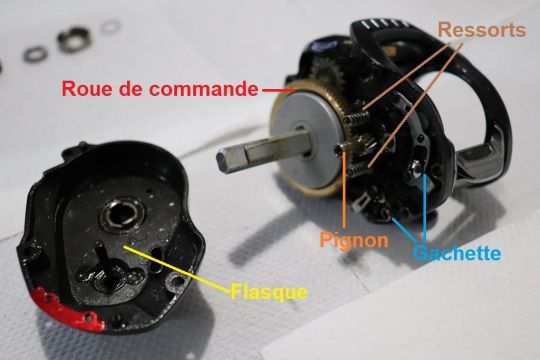

Assembly to be respected. - Remove the screws from the flange, be careful, they are not all the same length. Then, gently remove the flange and clean the inside.

Dismantled flange. - Gently disassemble the drive wheel, lock washers, springs, pinion and pinion carrier. Wash all parts and the inside of the reel. Use a toothbrush to remove grease from the gear teeth. Take the opportunity to clean the trigger mechanism to make sure it snaps back into place easily.

Clean the gear well. - Once the reel is cleaned and degreased, reassemble the pinion and its support.

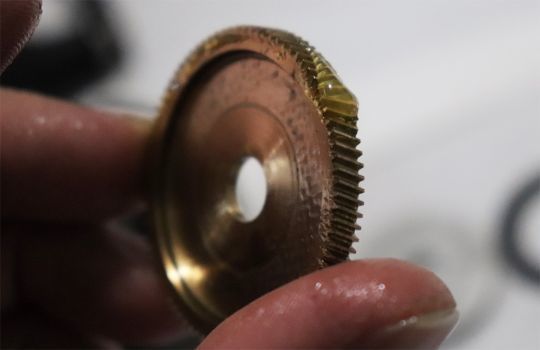

A reel should not exceed a certain amount of fat. - Now you can grease the reel again. Put a drop of grease on the control wheel and the plastic wheels, then spread it on all the teeth. You just need to put a thin layer of grease, which after a few turns of the crank, will spread itself on all the parts in contact. As for the brake washers, lightly tap them with grease on your fingers, to deposit a very thin layer of grease, which will serve to reduce the friction between the carbon and the metal. As for the springs, a drop of oil will keep them in good condition. You should also put a drop or two of oil on the trigger mechanism.

The control wheel is a critical part. - Reassemble the control wheel, brake washers and springs. Before installing the flange, place a drop of oil on the needle bearing of the flange and on the anti-reverse. Install the flange and complete the crank assembly.

- Put a drop of oil on each end of the spool shaft, then finish reassembling the reel.

Lubricate the coil shaft. - If possible, clean the worm and wire guide with compressed air. Put a drop of oil in the worm gear. Putting a drop of oil in this area regularly during the fishing season is a good thing to do. A hard spot here can quickly damage other internal parts.

Worm and wire guide.

And that's it! With practice, this process takes about 30 minutes. Some reels have a quick access hatch to put grease in. This allows you to lubricate the control wheel more often, but it doesn't remove the old grease, so a complete annual cleaning is still necessary.

As far as the friction brake is concerned, there is no particular maintenance to perform. You can remove the adjustment knob, unscrewing it completely, clean the inside and put a drop of oil on it, nothing more!

Note

Putting grease or oil on bearings does not lubricate them, as they are often sealed and greased for life. The purpose of putting grease or oil on bearings is to prevent outside elements, such as salt, from attacking the outer cage of the bearing. If you wish to use it, there is no contraindication, but you should not overdo it. A drop of oil or grease is more than enough.

If you put too much grease in the reel, the excess will end up in the reel and potentially in the control wheel or in the springs, which is not what you want. Indeed, too much grease will create stress in the movement of parts, while the purpose of this grease is precisely to facilitate these movements.

/

/